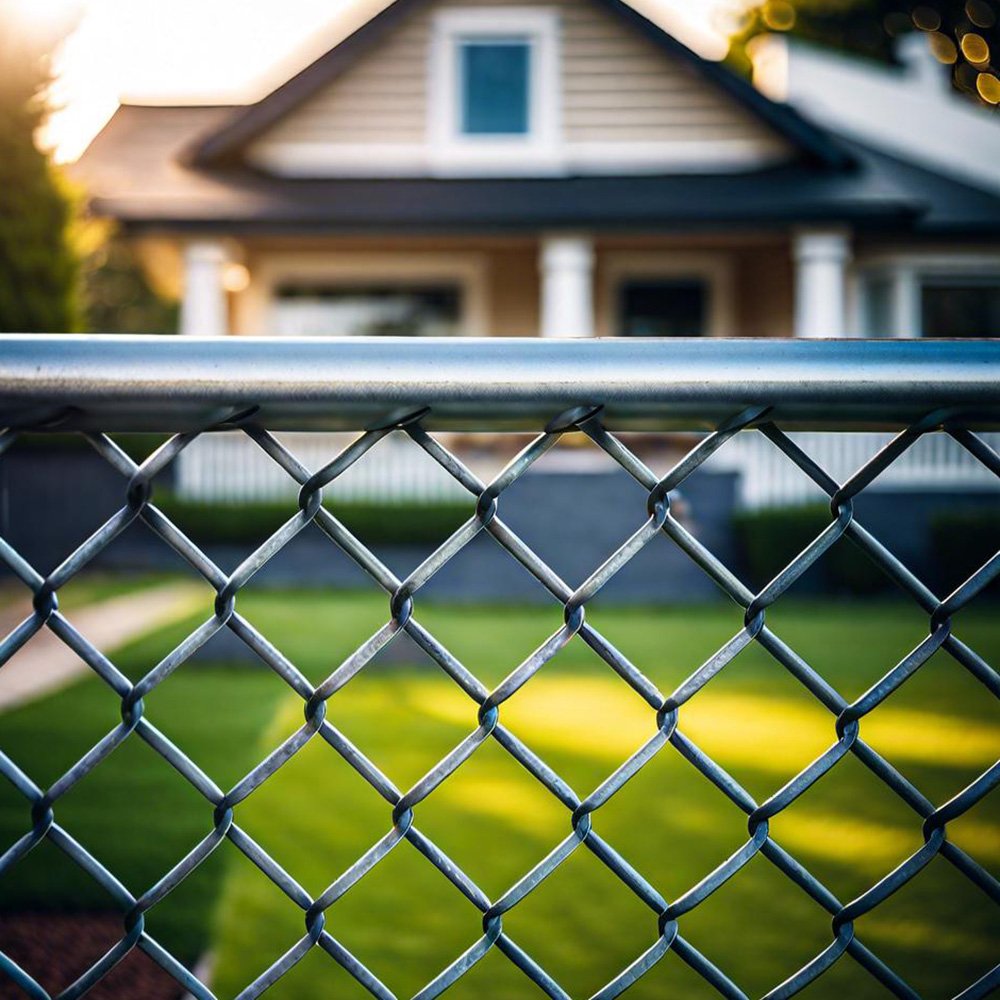

Aluminum Versus Aluminized Chain Link Fencing

Solid aluminum versus aluminized chain link fences is a subject that few manufacturers discuss. Because of this, it makes it confusing to know the differences and which one to buy. This breakdown will discuss each type's benefits and hopefully answer any questions about whether to buy aluminum chain link or aluminized chain link fencing.

Quick Reference For The Differences Between Solid Aluminum And Aluminized Chain Link

| Solid Aluminum | Aluminized Steel |

|---|---|

| Lightweight | Heavier (Steel) |

| High Corrosion Resistance | Moderate Corrosion Resistance |

| Non-Magnetic | Magnetic |

| Great For Reflectivity Of Heat And Visible Light (Better Conductor) | Moderate Reflectivity Of Heat And Visible Light (Okay Conductor) |

| High Strength To Weight Ratio | Shares Strength Properties Of Steel And Low Weight Of Aluminum |

| More Expensive | Less Expensive |

Solid Aluminum Chain Link Manufacturing Process

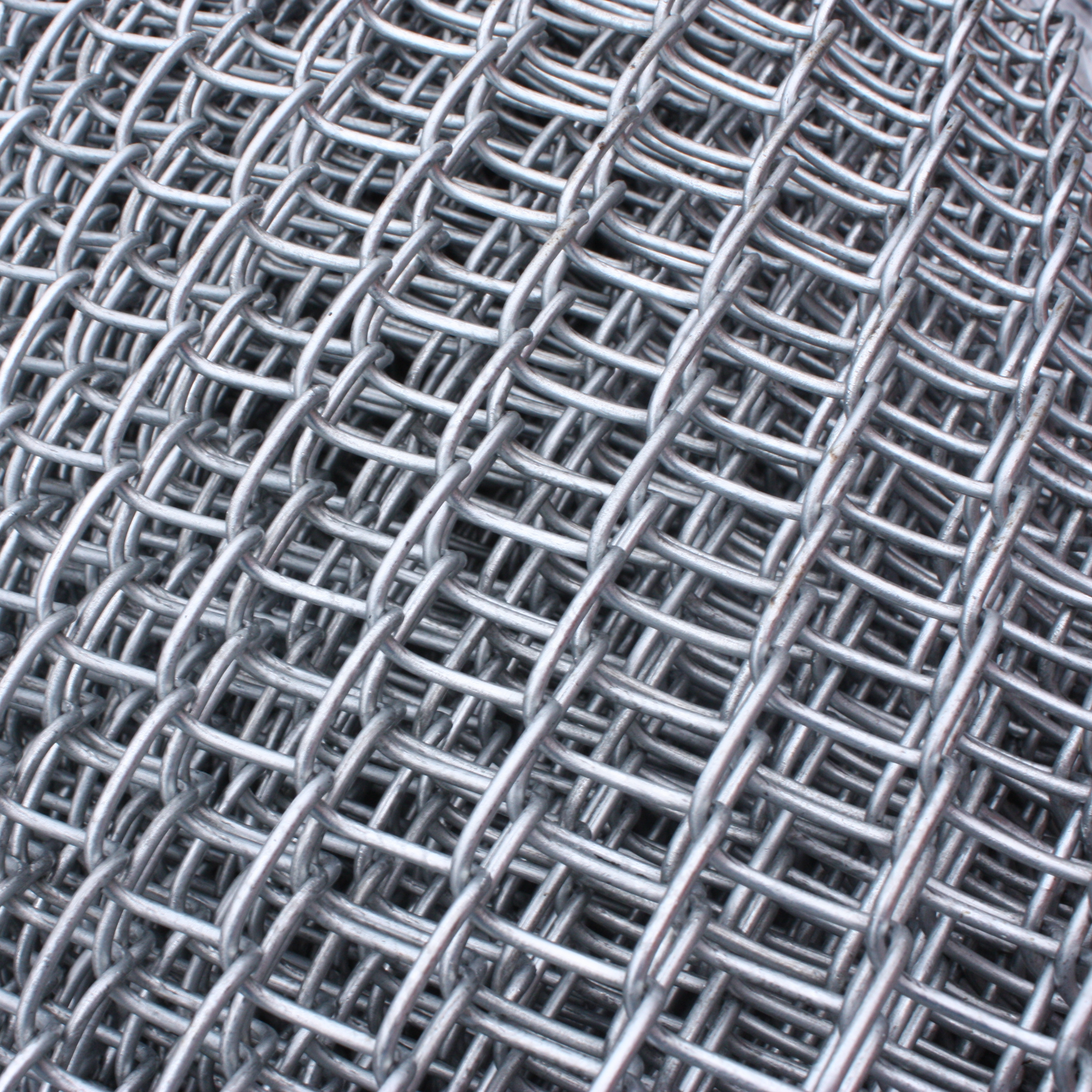

The manufacturing process of all types of chain link fence fabric, sometimes called chain link netting, is mostly the same. The big difference would be the material and aluminizing process, adding in a couple of extra steps. It starts with a giant spool of solid aluminum wire. From there, the wire is straightened out and fed into machines that bend the wire into a zigzag pattern. This allows each wire to intertwine with the other, forming the classic-looking diamond pattern typical for chain link fences. The ends or sides of the woven fabric is then crimped in a "knuckle twist" pattern.

Aluminized Steel Chain Link Manufacturing Process

The process for making aluminized chain link mesh/fabric is almost identical to solid aluminum except for the process of aluminizing the metal. The steel is coated using a method called "hot-dipping." This is similar to the galvanizing process, except an aluminum-silicon alloy is used instead of using zinc. Dipping the metal in the alloy assures a strong, metallurgical bond. The bond allows the properties of both steel and aluminum to be used. Aluminum has extreme corrosion resistance, while steel has high strength. After the hot-dipping process has been completed, the wire is cut and made into a spool and continues with the same process as described above.

Why Choose One Over The Other?

There is not necessarily a chain link fence type that is the best for everything. It is dependent on the application. What will it be used for? Where will it be installed? Is the fence going to be near salt water? These questions should be asked before purchasing any chain link part or accessory.

Solid Aluminum has the best corrosion resistance. Corrosion resistance is beneficial if the fence will be used near any salt water (roughly 2-5 miles away). Salt and other corrosive agents are detrimental to fences. Galvanized fences can be destroyed in as little as 5 years if installed near coastal areas. Even aluminized steel fences can be worn down quickly due to corrosion. The reason for this is even though the rods are hot-dipped in the aluminum-silicon alloy, and the wire is cut afterward, exposing the bare steel. Now, there are manufacturers that hot-dip after the cutting has been completed, but that is not an industry standard.

Aluminized chain link has a much lower cost than solid aluminum. This is useful where corrosion resistance is not a top priority. The strength of steel is an added benefit while offering better corrosion resistance than standard galvanized steel.

Maintaining and keeping up with any style of chain link fence can seem like a daunting task; however, our chain link products are sure to provide durability, ease of installation, and, most importantly, low cost. Please Reach Out To Our Sales Team to learn more about our complete aluminum chain link fencing parts, accessories, and hardware!

Contact Us